BHR SERIES

ROTARY sURFACE GRINDERS

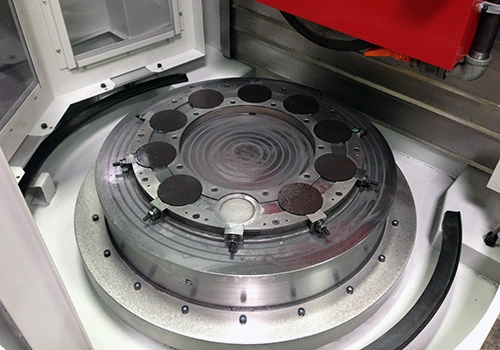

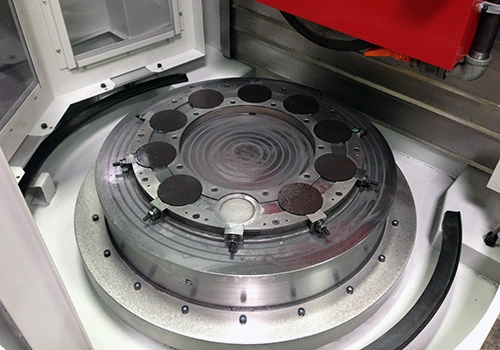

The BHR-500 CNC Rotary Surface Grinder offers a rigid and robust surface grinding solution paired with an easy-to-use programming interface. It features a 20″ magnetic chuck built on a very sturdy, stable granite structure and uses state-of-the-art polymer concrete for extreme dampening capability. Stiffness and accuracy are the two main reasons why our customers choose this platform for their grinding needs. Because of its very high rigidity, this machine is well suited for grinding tough materials such as CBN, PCD, or Carbide.

TECHNICAL SPECIFICATIONS

BHR-500

X-Axis Travel

250mm

Z-Axis Travel

300mm

Magnetic Chuck Diameter

500mm

MACHINE HIGHLIGHTS

-

Designed and Built in the USA

-

Solid epoxy granite machine base for extra rigidity

-

Work spindle with programmable constant surface speed control

-

Oversized powerful servo motors for x-axis and z-axis

-

Preloaded Heavy-Duty linear bearings

-

Absolute linear scales for positioning control

-

Heavy duty wheel spindle

-

Specially designed continuous stick-dress unit – air actuated

-

Automatic part touch off for “zero” start capability

-

Automatic part thickness measurement cycle

-

ROBOT load/unloading station with table positioned pallets

TECHNICAL SPECIFICATIONS

BHR-500

X-Axis Travel

250mm

Z-Axis Travel

300mm

Magnetic Chuck Diameter

500mm

MACHINE HIGHLIGHTS

-

Designed and Built in the USA

-

Solid epoxy granite machine base for extra rigidity

-

Work spindle with programmable constant surface speed control

-

Oversized powerful servo motors for x-axis and z-axis

-

Preloaded Heavy-Duty linear bearings

-

Absolute linear scales for positioning control

-

Heavy duty wheel spindle

-

Specially designed continuous stick-dress unit – air actuated

-

Automatic part touch off for “zero” start capability

-

Automatic part thickness measurement cycle

-

ROBOT load/unloading station with table positioned pallets