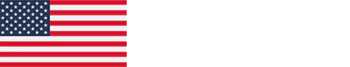

BT-3000R

TURBINE SHAFT GRINDER

The Basaran BT-3000R Turbine Shaft Grinder is designed for high precision machining, delivering unmatched accuracy for complex turbine shaft production. Designed for the aerospace, energy, rail and automotive industries, this advanced CNC grinder ensures smooth surfaces and perfect alignment every time. Equipped with state-of-the-art control systems and customizable features, it handles a wide range of shaft sizes and materials, from high-strength alloys to precision steels. Enhance your production efficiency and precision with the CNC Turbine Shaft Grinder, the ultimate solution for high-precision turbine shaft machining.

TECHNICAL SPECIFICATIONS

BT-3000R

X-Axis Travel

20″

Z-Axis Travel

144″

Max Grinding Dia.

24″

Max Grinding Length

144″

Grinding Wheel Dia.

24″

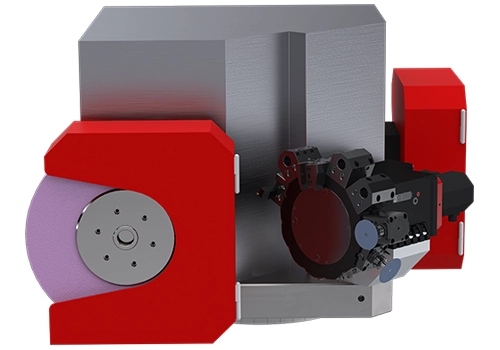

DUAL-SPINDLE TURRET

HEAVY DUTY WORK SPINDLE

MACHINE HIGHLIGHTS

-

Designed and Built in the USA

-

Solid epoxy granite machine base for extra rigidity

-

Heavy-Duty Work Spindle

-

20” dia. Face Plate with T-Slots

-

Touch Probe for Part Set-Up

-

Sensor for wheel calibration and dress touch-off

-

0.1 micron linear scales

-

Automatic lubrication for ball screws and guide ways.

-

BASARAN motorized 20hp grinding spindle

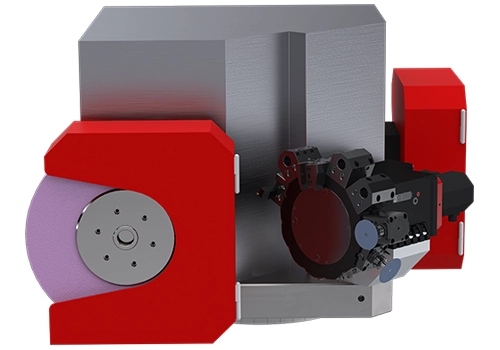

MACHINE HIGHLIGHTS

-

Designed and Built in the USA

-

Solid epoxy granite machine base for extra rigidity

-

Heavy-Duty Work Spindle

-

20” dia. Face Plate with T-Slots

-

Touch Probe for Part Set-Up

-

Sensor for wheel calibration and dress touch-off

-

0.1 micron linear scales

-

Automatic lubrication for ball screws and guide ways.

-

BASARAN motorized 20hp grinding spindle

TECHNICAL SPECIFICATIONS

BVG-1400

X-Axis Travel

20″

Z-Axis Travel

144″

Max Grinding Dia.

24″

Max Grinding Length

144″

Grinding Wheel Dia.

24″

DUAL-SPINDLE TURRET